Forging

Our screw presses range from 270 tons up to 1200 tons of forming capacity. This line of hot forging equipment is supplemented by mechanical presses for trimming and punching. Multiple furnaces at each hot forging line allow for the right heating depending on the chosen alloy. We have to empathize our special focus on individual furnaces for each material. This sets us apart to other forges. Implant grade Titanium is only heated in a dedicated furnace. We have other dedicated furnaces for aluminium and copper alloys, sometimes multiple at one forging line. Very sensible aluminium alloys are only heated by air and are not allowed to be blasted directly by gas jets. This allows us to heat the parts to exact temperatures with minimal deviations and minimal risks due to overheating due to errors in the production process.

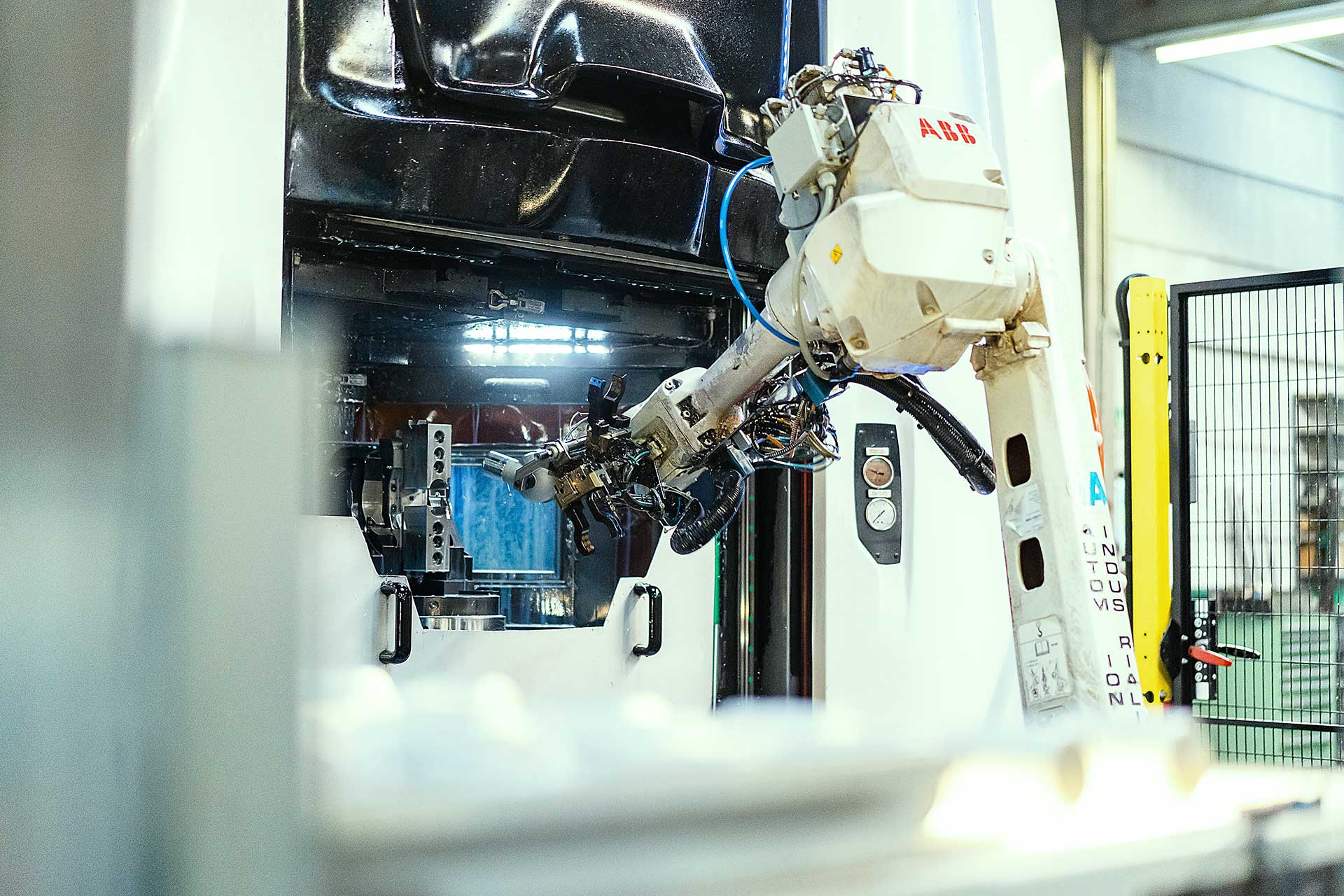

We can handle parts from 10g up to 20kg. For suitable lotsizes we can use automatic handling systems.

A fully automatic heat-treatment of the forgings finishes the process of the raw part.

Advantages forging:

- Less risk for leakage

- gas-proof requirement

- Less rework for decorative parts

- Lower scrap due to no bubbles/cavities

- Higher material strength for high-performance parts

- More/different design options

- High-pressure die casting tools to expensive

- Reduced part cost compared to die casting

- Sometimes dies can be mixed and combined to forge variations

Our advantages:

- Dedicated and specialized furnaces for each material

- Air-Heating of sensible parts only. This allows stable processes for aluminium alloys that have a high risk of failure when overheating.

- Multiple furnaces per forging line for more flexibility

- Sub-presses that allow hollow areas not in forging direction

- Lean processes and a skilled operator team

Vergleich der Umformtechnologien

| Forging | High-pressure casting | Die casting | Sand casting | |

|---|---|---|---|---|

| Porosity | Very good | Good | Neutral | Not good |

| Material strength | Very good | Good | Neutral | Not good |

| Tooling costs | Neutral | Very high | Neutral | Low |

| Precision | Good | Very good | Good | Low |

| Reworking of tool | Easy | Hardly possible | Possible | Very easy |

| Lotsizes | >500 | High lotsizes needed | >500 | >1 |

| Surface quality | Very good | Very good / Good | Neutral | Very bad |

| Part cost | Low | Very Low | Low | High |

Let’s forge our future!

Kühr is your reliable partner in forging non-ferrous and light metals.