Lightweight

Aluminium as problem solver for weight restricted parts.

Many applications ask for light and highly dynamic parts. We can forge most of the major high-strength aluminium alloys, which can be an alternative for traditional materials like steel. There are many areas were a light and highly dynamic aluminium forging can provide benefits to the complete product. Our customers have successfully substituted steel by aluminium to increase productivity through faster moving parts in their machinery. In the Energy sector, copper or brass alloys can be replaced by silver plated aluminium parts. This can result in savings of up to 90% of material usage when transitioning form copper to aluminium for live parts.

Use Case

Lightweight Hydraulics: Aluminium replaces Steel

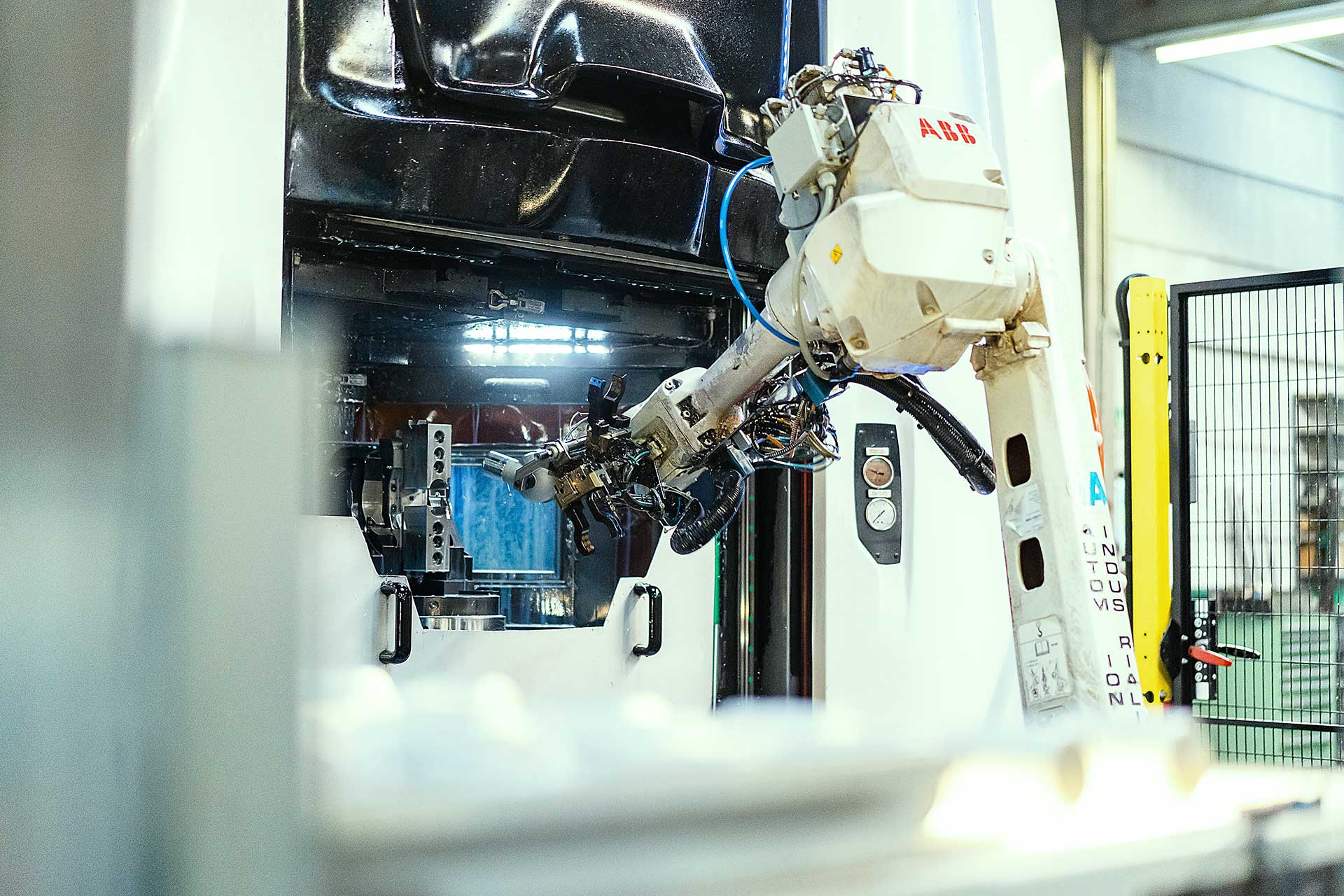

A welded 3-part steel assembly had to be replaced by a single machined forging from aluminium. The aluminium parts had to be 100% compatible to the steel part so the right alloy had to be selected to fulfil all mechanical requirements. As a result, the part weight could be drastically reduced. As only one part had to be machined, and the welding process could be omitted, the complete process could be automated also for medium lot sizes. This resulted in costs savings through a more efficient production methodology.

Let’s forge our future!

Kühr is your reliable partner in forging non-ferrous and light metals.