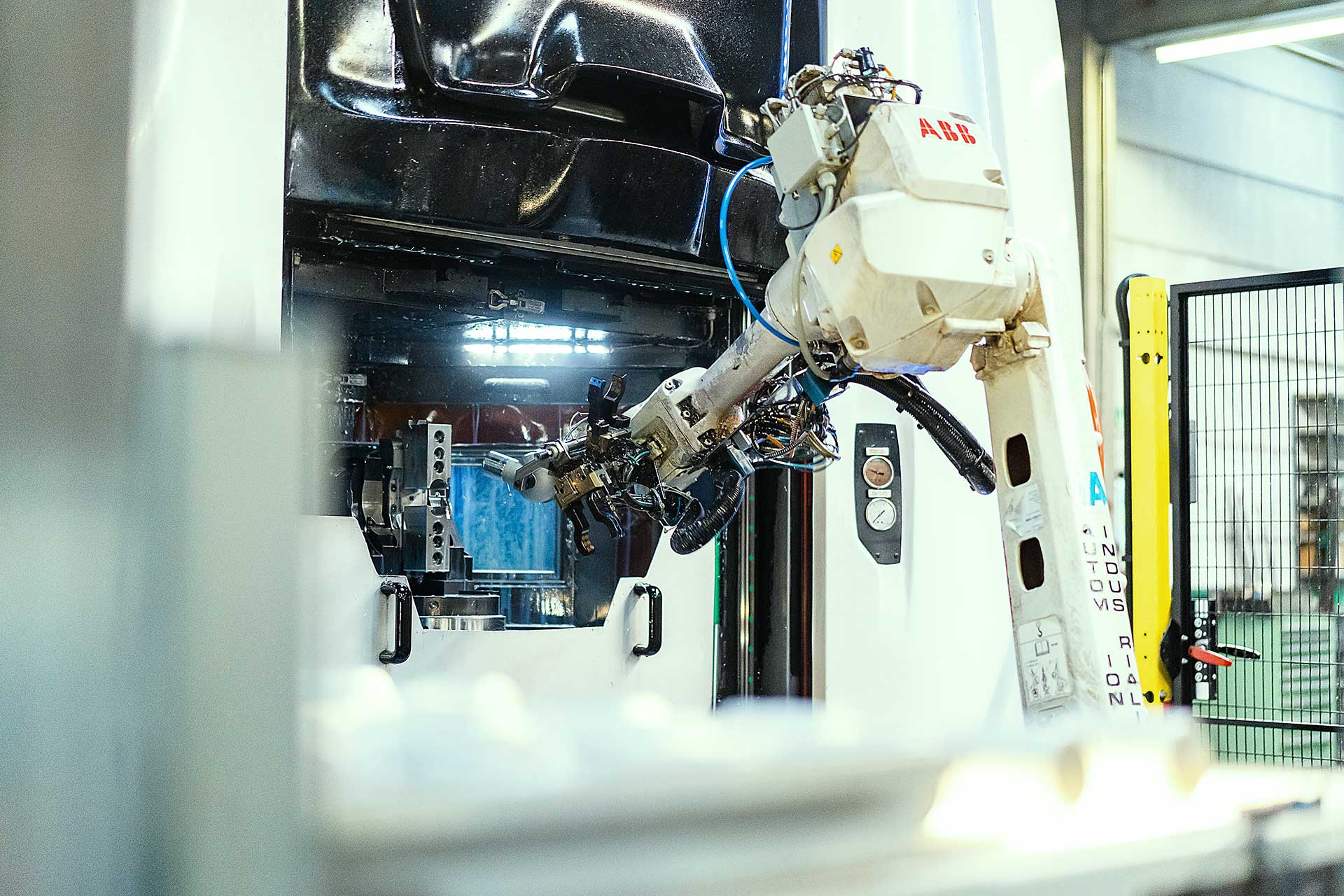

Machining

Over 20 CNC Machines allow for most of the relevant machining of the raw parts in-house. We have chosen a very broad strategy concerning our investment in new CNC machinery. We can do 5-axis machining as well as high-lot sizes on our fully automated transfermachines. We se it as a challenge to invest in the new technology and asses new strategies for production of new and old products. One of our main goals is a manless lights-out production. Additional focus is set on zero waste due to errors and quality issues. Relevant processes are monitored live, to allow for fast response times. Our processes allow for manless production starting at 250 pieces lot-sizes. From Forging to finished part in one 100% automated process with included n-process quality checks, that’s how we love to work.

Our advantages

- Clever machining strategies start at the design of the forging. This Is our daily work and allows us to set us apport from our competitors. Our high-level of automation is a result of this philosophy.

- Lights-out production starting at 250 pieces lotsize

- From raw part to finished part in one process minimizes risk of errors

- In-Process measurement to anticipate problems and allow for correction

- We invest in new technologies to allow for competitive manufacturing processes In Europe

- CNC, heat-treatment, blasting, tumbling, printing in house to reduce lead times and cost

- Reliable and diverse net of partners for plating and other related subcontracting

Let’s forge our future!

Kühr is your reliable partner in forging non-ferrous and light metals.