Mechanical Engineering

Forged parts have many advantages.

Forged parts guarantee bubble and pore-free surfaces. This is ideal for safety relevant hydraulic applications.

Sealing areas have nearly zero risk including bubbles or pores that can cause leakage. Forged parts allow for complex geometries, while providing high-strength for highly stressed parts. There are weldable, corrosion resistant, high strength, or decorative alloys that can be forged. We can provide solutions from aluminium or can fall back to brass or copper alloys if corrosion resistance, strength or sliding-friction requirements are of importance. Just send us your cast or milled parts, and we can check them for their saving potentials when realised as a forging.

Use Case

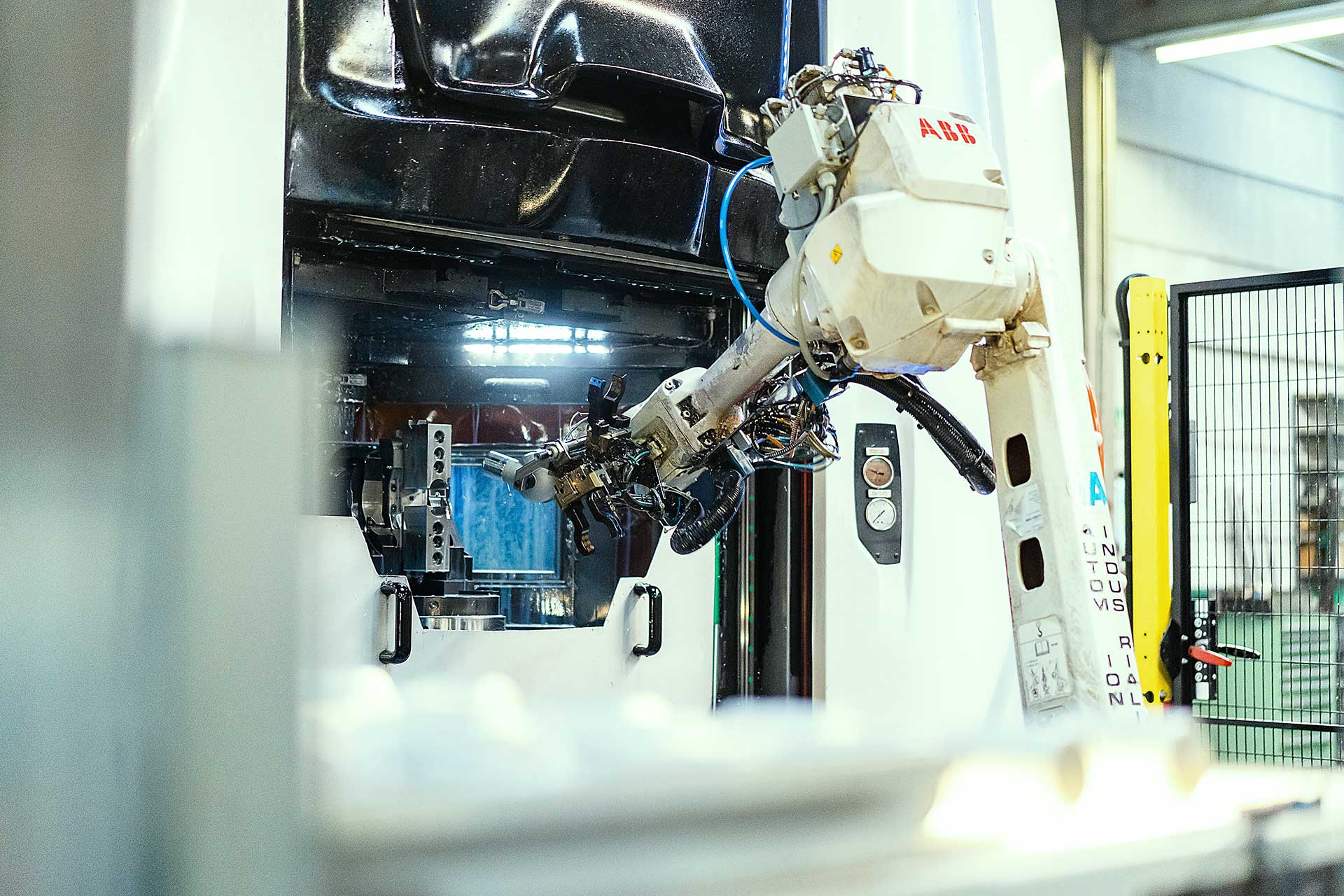

Highly dynamic parts.

Every ounce counts! Aluminium can be a problem solver where steel casting reach their limits.

In this use case a steel part was replaced by a forged part out of a high-strength aluminium alloy. This allowed for a more dynamic part and ultimately faster cycle times of the machine that it was part of.

Let’s forge our future!

Kühr is your reliable partner in forging non-ferrous and light metals.