Medical Engineering

Focus on – Highly stressed, corrosion resistant and decorative requirements.

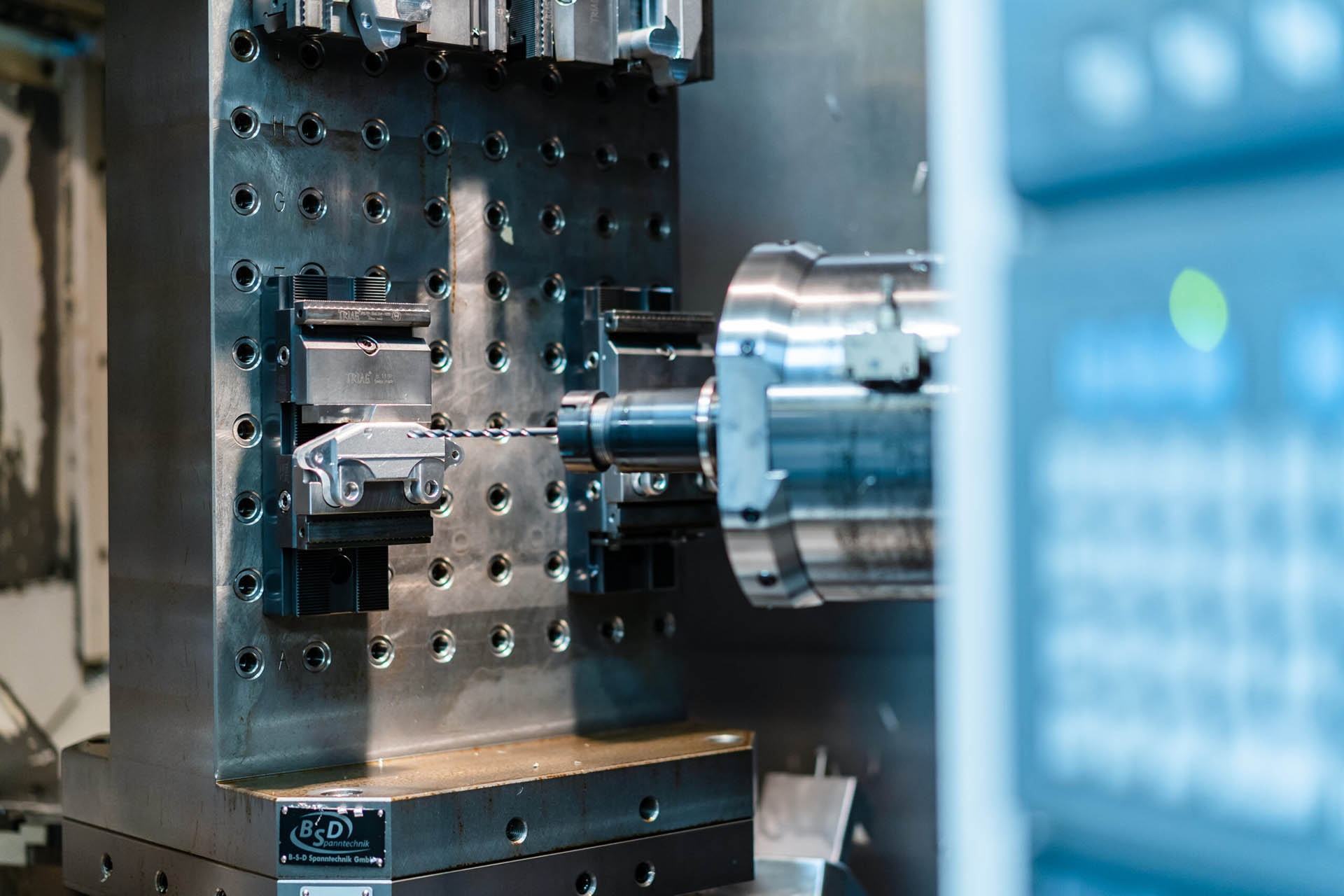

The requirements for medical products are very varied and challenging. The forging of implants from titanium alloys is especially demanding. Stable and monitored processes are a prerequisite to supply such implants.

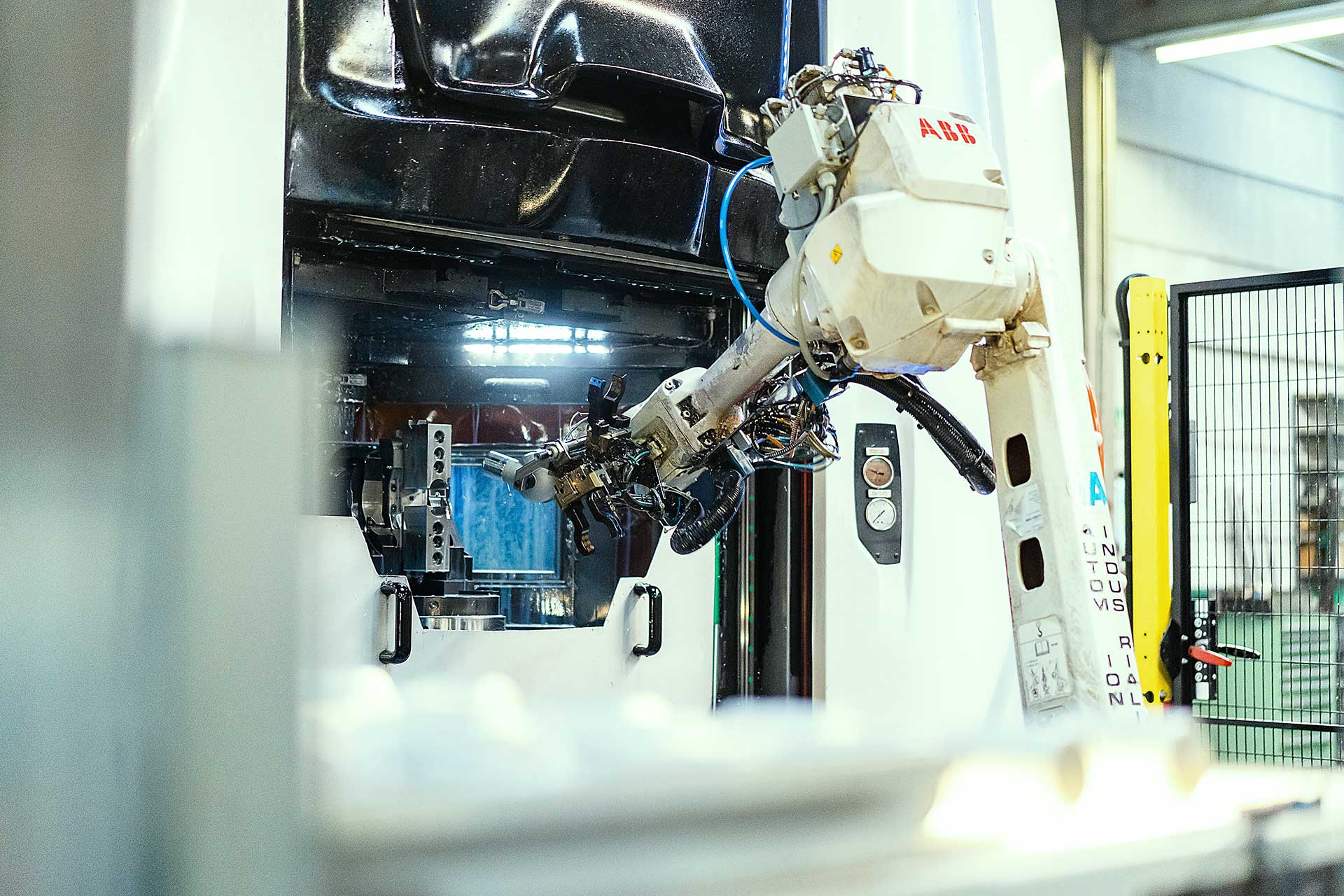

As our processes are fit for these products, we can apply the gained knowledge to other product classes as well. We have done so for products for hospital OP or laboratories. Typically, one must solve the problem of producing safety relevant parts that are highly stressed, corrosion resistant and have a flawless surface. We can take a look at your requirements and can check if a Forgings might help to overcome certain boundaries.

Use Case

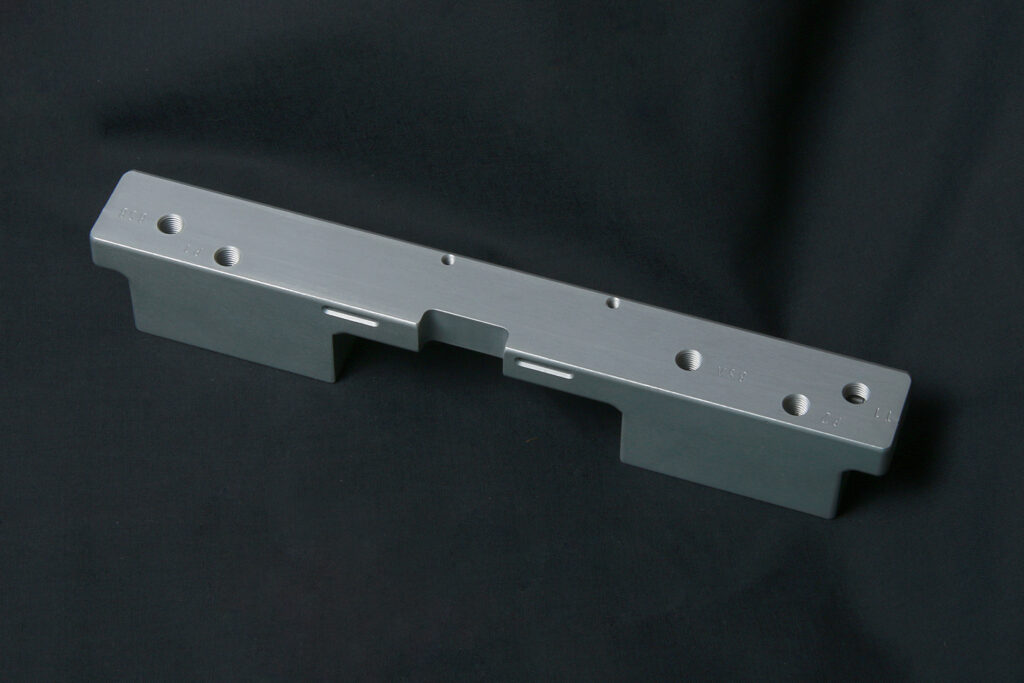

Hydraulic Block for hospital operating table

There is zero tolerance for failure of hospital equipment. Forged parts may provide a solution to gain some additional safety margin. Better mechanical properties and higher surface qualities compared to castings may help to prevent failure when choosing a forged part. In this case leakage was minimized compared to an alternative casted part.

Let’s forge our future!

Kühr is your reliable partner in forging non-ferrous and light metals.