Energy and Infrastructure

Live parts for high and medium voltage applications.

Im Bereich der stromführenden Bauteile haben wir uns schon in den 1970er Jahren erfolgreich in Europa platzieren können. Unsere Bereitschaft zur Flexibilität und der Drang sich ständig weiterzuentwickeln hat uns z

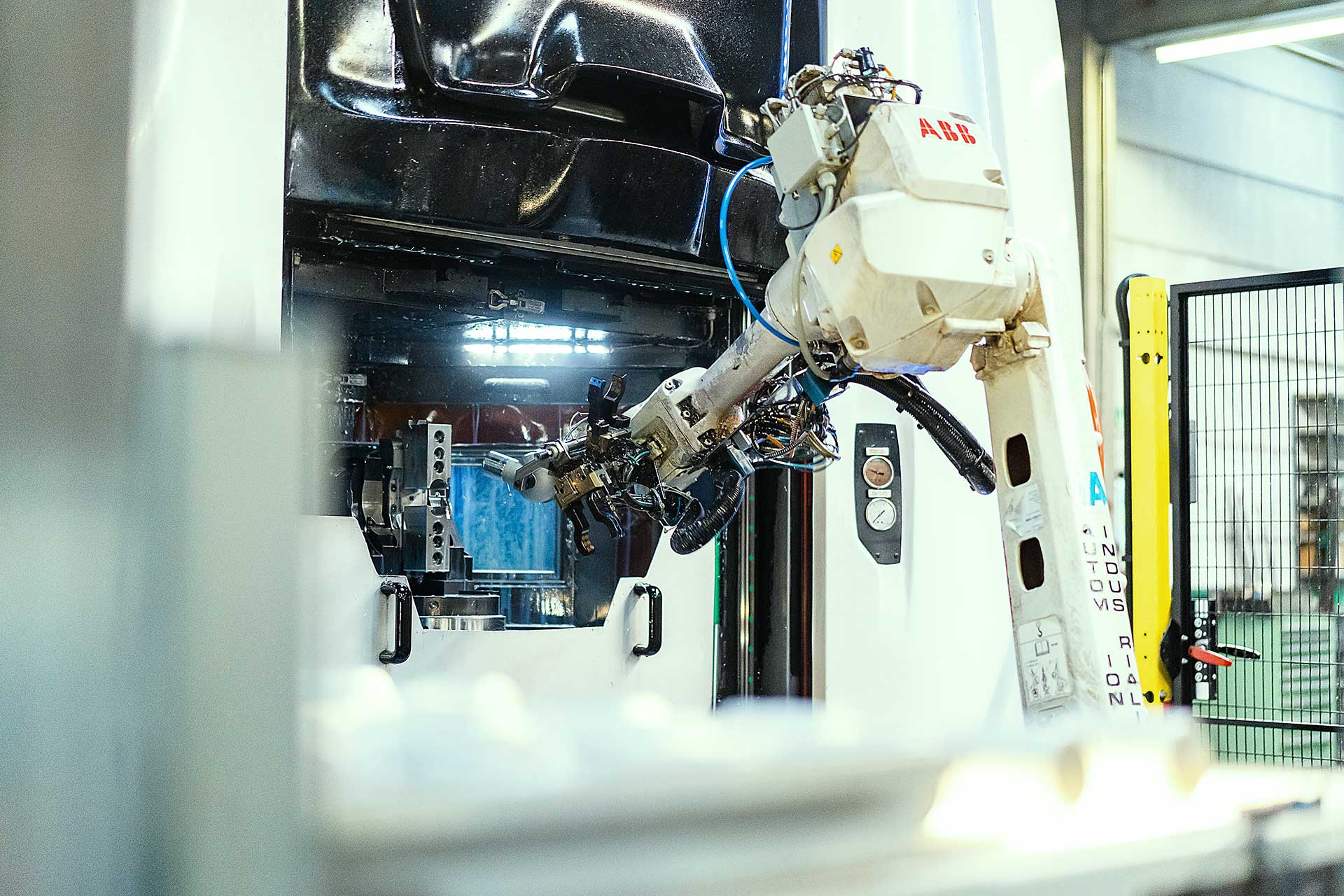

We started producing forged inserts for high- and medium voltage applications in the 1970s. As one of the first suppliers that can forge Aluminium, Copper, and brass parts we have gained a large customer base in Europe. Our continuous improvement of our processes as well as offering complete products like inserts with plating, have made us strategic partners for the major players in this industries. We are eager to support in the development of new parts, and can provide fast and flexible solutions from prototypes to series. Our highly automated production helps us to stay competitive and allows us to produce this usually heavy parts in central Europe. We are also a supplier for certain forged product for the infrastructure industry, like clamps for overhead wires for the railway or subway systems. We are also forging high performance alloys like CuNi or other special copper alloys, and can therefore provide a complete portfolio for most of our customers.

Use Case

One tool, two different materials. Optimized for each requirement.

One of our customers wanted to save costs by producing the high runners with aluminium as base material and only the high end variants should be produced out of copper alloys. As the same and the same production methods could be used, we could generate substantial savings with the added flexibility of inserting small lot sizes of the high-end variant with minimum effort.

Let’s forge our future!

Kühr is your reliable partner in forging non-ferrous and light metals.